Welcome to the world of custom apparel. Whether you’re starting your own t-shirt business or want to create personalized designs for yourself and your loved ones, investing in a heat press machine is a game-changer. Heat press machine reviews for t shirts will help you get a better understanding of the things that you should look for when making a purchase. Here, we’ll walk you through the essential features to consider when buying a heat press machine specifically for t-shirts. We’ve got you covered from heat plate size to temperature range, pressure adjustability to timer function. So, let’s dive in and find the perfect heat press machine that will take your creativity and style to new heights.

Heat Plate Size

When it comes to heat press machines, one of the key factors to consider is the size of the heat plate. The heat plate, or platen or platen press, is where you’ll place your t-shirt for printing. A larger heat plate offers several advantages. It allows you to work with a variety of t-shirt sizes and designs. Whether you’re pressing small logos on children’s tees or full-size graphics on adult-sized shirts, having a spacious heat plate ensures that you can accommodate different dimensions. Moreover, a bigger surface area means more efficient production. With a larger heat plate, you can print multiple garments simultaneously or even press larger designs without any hassle.

Temperature Range

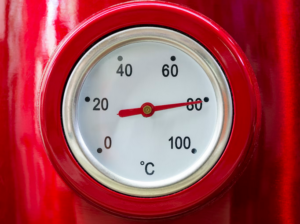

When it comes to buying a heat press machine for t-shirts, one crucial feature to consider is the temperature range. This refers to the range of temperatures the machine can reach and maintain during heat transfer. Having a wide temperature range is essential because different materials and designs require different heat settings. For example, some fabrics may require lower temperatures to avoid scorching or burning, while others may need higher temperatures for proper adhesion. A heat press machine with a limited temperature range may restrict your options and limit your ability to work with certain materials or achieve desired results. On the other hand, a machine with a wider temperature range gives you more flexibility and control over the heat transfer process.

When it comes to buying a heat press machine for t-shirts, one crucial feature to consider is the temperature range. This refers to the range of temperatures the machine can reach and maintain during heat transfer. Having a wide temperature range is essential because different materials and designs require different heat settings. For example, some fabrics may require lower temperatures to avoid scorching or burning, while others may need higher temperatures for proper adhesion. A heat press machine with a limited temperature range may restrict your options and limit your ability to work with certain materials or achieve desired results. On the other hand, a machine with a wider temperature range gives you more flexibility and control over the heat transfer process.

Pressure Adjustability

One of the key features to consider when buying a heat press machine for t-shirts is pressure adjustability. This feature allows you to control the amount of pressure applied during the heat transfer process, giving you greater flexibility and precision in your designs. With pressure adjustability, you can easily customize the settings based on the type of fabric and design you are working with. Different materials require different pressure levels to achieve optimal results, so having this feature ensures that your t-shirt prints come out crisp and professional every time. Whether you’re printing on delicate fabrics or thick garments, adjusting the pressure gives you peace of mind, knowing that your machine can handle any project. It also allows for more consistent results across multiple shirts, as each may require slightly different pressures depending on size and composition.

Timer Function

When it comes to buying a heat press machine for T-shirts, one of the important features to consider is the timer function. This feature allows you to set a specific duration for each pressing cycle. The timer function ensures consistency in applying heat and pressure on your T-shirts. You can easily control the time required for each transfer, resulting in consistent and professional-looking prints every time. With a timer function, you can avoid overexposure or underexposure of your designs on the fabric. It eliminates guesswork and helps maintain quality throughout your printing process.

Carefully evaluate these features when purchasing a heat press machine to confidently create stunning t-shirt designs while maximizing productivity in your business or personal projects. Have you bought a heat press machine lately? Let us know what features you have considered. We hope that you have found this blog post helpful.

ProCalV5 is a comprehensive calibration management software that offers a range of features for managing calibration processes, including automated calibration scheduling and tracking, equipment history tracking, and customizable calibration procedures. The software also offers reporting features and is highly customizable, making it an ideal choice for businesses with specific needs.

ProCalV5 is a comprehensive calibration management software that offers a range of features for managing calibration processes, including automated calibration scheduling and tracking, equipment history tracking, and customizable calibration procedures. The software also offers reporting features and is highly customizable, making it an ideal choice for businesses with specific needs.